COMPANY

COMPANY

In 1980, "Sueheung Yanghaeng," an apparel accessories company, was founded in Hapjeong-dong, Seoul. The company supplied apparel accessories to renowned global brands such as NIKE, ADIDAS, GAP, and FILA. By developing silk screen printing and back-number films for sports uniforms, the foundation of the business was established. The business direction and values formed during this period continue to this day.

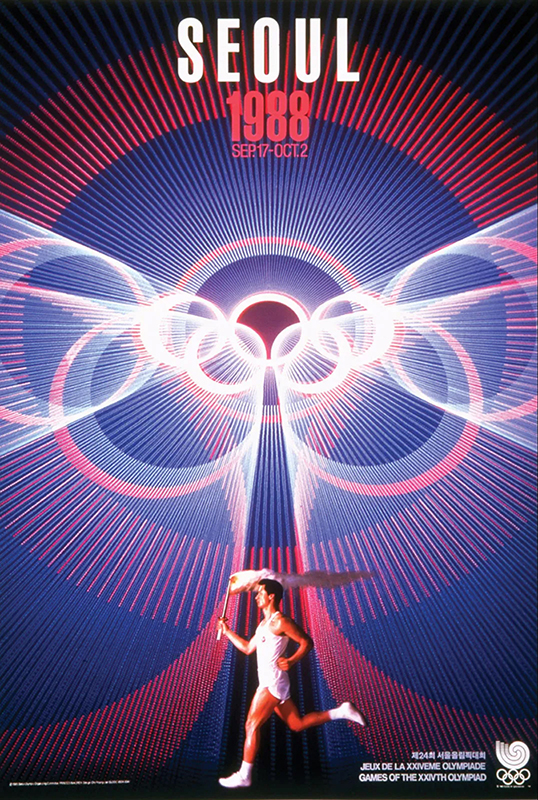

Taking inspiration from the 1988 Seoul Olympics, the company began developing reflective fabrics. Previously, imported products had been processed and sold, but this marked the first effort to develop proprietary products.

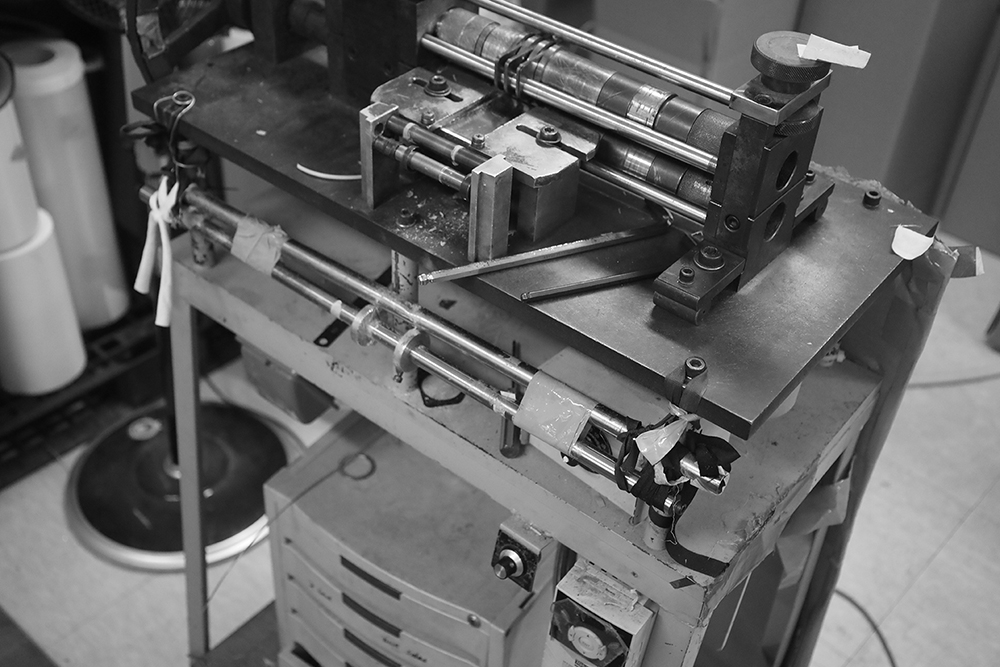

To expand the market for apparel accessories, additional processing production lines were secured. Investments were made to diversify the industry by expanding silk screen printing and uniform back-number film printing, as well as incorporating sewing, adhesion, and high-frequency equipment. This was a turning point in becoming a comprehensive apparel accessories company.

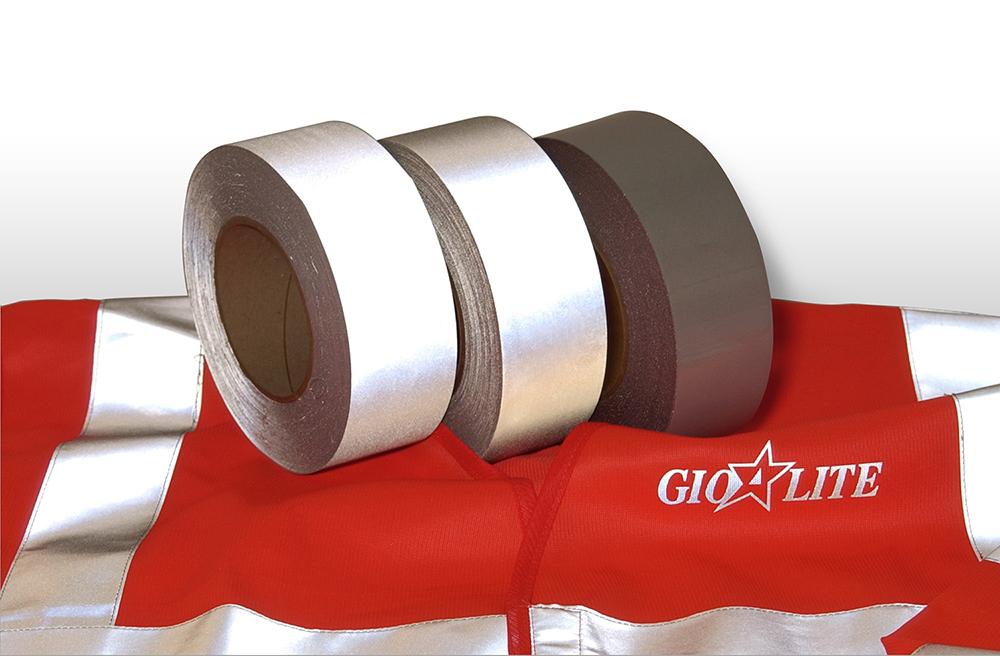

After five years of development and effort, the company successfully localized retro-reflective material. As the first company in South Korea to achieve this in a market dominated by multinational corporations, the product gained popularity due to its affordability and quality, which rivaled imported products.

Chairman Choi Sang-seok had experience in the bag export industry before founding the company. Based on this expertise, bag manufacturing and export operations began. High-quality products were supplied to various Japanese brands such as SAKURA, Barbie, Miffy, and Shodo calligraphy bags. Bags have since become a core product of GIOLITE.

Following the expansion of the bag business in 1995, a manufacturing plant was established in Vinh Phuc, Vietnam. This allowed the company to build its own bag manufacturing infrastructure and maintain long-term business relationships with partners that continue to this day.

In 1997, the company began producing and selling products under the "GIOLITE" name, a brand that remains to this day. The brand identity and values established at that time—placing "quality first"—continue to guide the company's manufacturing philosophy.

SUEHEUNG REF was established to specialize in the processing of apparel accessories. By recruiting dedicated professionals within each corporate division, the company ensured focused expertise in various fields.Membership with the Korea International Trade Association (KITA).Patent obtained from the Korean Intellectual Property Office for the transfer method of decorative patterns on clothing.

SUEHEUNG REF CO.,LTD was recognized for its achievements and selected as a promising export SME, acknowledging its contributions to national economic growth through exports.

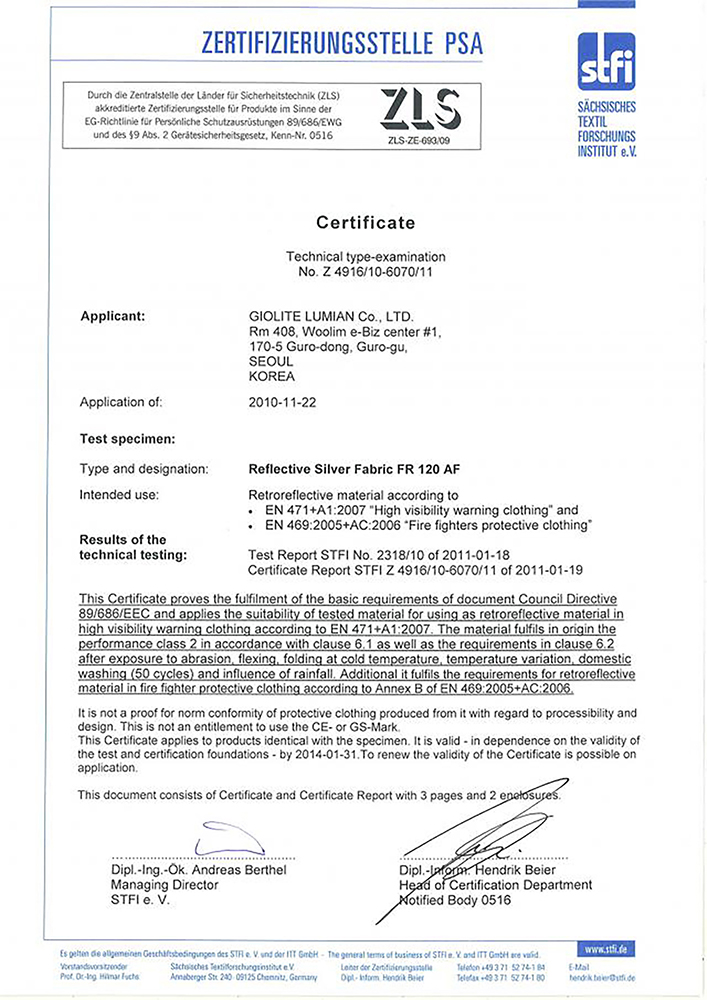

GIO-LITE's first applied product for industrial use, reflective tape, obtained European certification, marking the beginning of international recognition for GIOLITE products.Acquisition of CE mark for reflective safety vests.Establishment of a safety vest production line in Vietnam.

Following European certification, GIO-LITE's reflective tapes also acquired U.S. certification, solidifying its reputation in Asia, Europe, and North America. The company diversified its reflective materials lineup to include sew-on reflective materials, heat transfer film-type reflective materials, and various color variations.

Acquisition of European certification for flame-resistant reflective tape (EN 469, EN 532, EN 533).

ISO 9001 / 2000 certification obtained.Recognition as a venture company by the Small and Medium Business Administration.

In addition to glass bead-type reflective materials, microprism-type reflective materials were developed for industrial safety apparel and flame-resistant clothing. Microprism reflective films are widely used in road signs, traffic cones, and lane dividers due to their high durability and brightness.

The establishment of GIOLITE-LUMIAN marked the company's official expansion into overseas markets with a dedicated sales infrastructure.

GIO-LITE began seamless (bonded) welding technology for waterproof, highly durable, and easy-to-use apparel applications. This technology has been a core competency of GIOLITE ever since.

GIOTECH-INTERNATIONAL Co., Ltd. was founded in Yangsan, Gyeongsangnam-do, as a specialized manufacturer of reflective materials. By completely separating the reflective film manufacturing sector, we were able to foster specialized personnel and focus on intensive R&D.

WORLD FLEX was founded in Pocheon, Gyeonggi-do, as a specialized brand for heat transfer films, which are commonly used for numbers on sports uniforms. Today, this product is a major pillar of Geoflex.

GIO-SOLTECH CO.,LTD was founded in Wonju, Gangwon-do, specializing in biodegradable resins. The company produces and sells polymerized and compounded products related to petroleum-based biodegradable resins such as PBAT and PBS.

GIOLITE-LUMIAN CO.,LTD. was recognized for its R&D efforts and performance, earning the INNO-BIZ designation, which acknowledges companies with strong future growth potential.

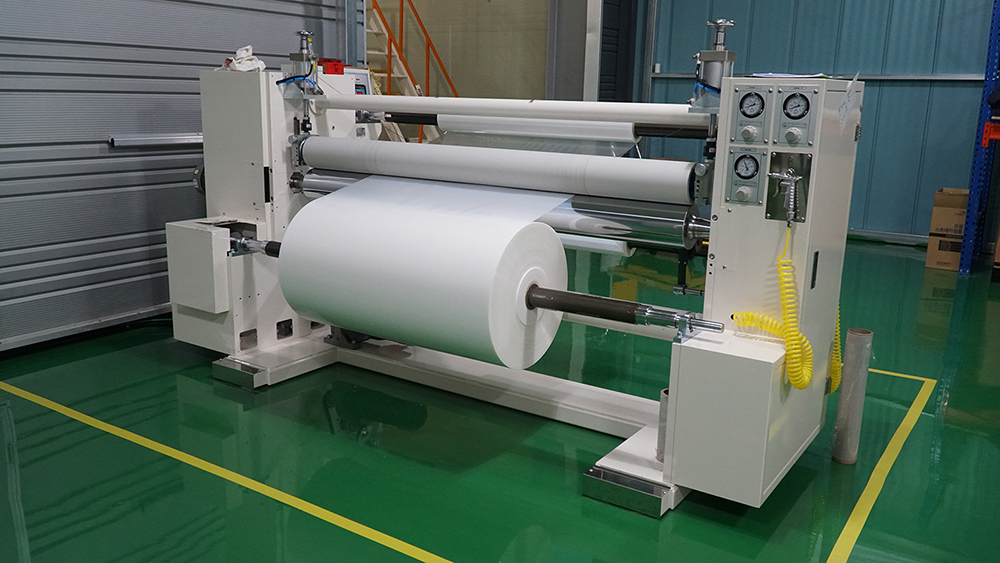

A second factory was added in Pocheon. Previously, all processes—film development, coating, and cutting—were carried out in a single facility. The expansion allowed certain coating-related processes to be moved to the new plant, increasing logistics capacity and enabling the development of more products.

SUEHEUNG REF CO.,LTD. established a welding processing plant and design studio. The company expanded its welding components division by adding an in-house processing facility and hiring specialized personnel. The new plant also allowed the company to handle the entire clothing accessory manufacturing process. Additionally, the design studio enabled cost adjustments and product development beyond simple production work.

The expansion of coating equipment increased the company's logistics handling capacity.

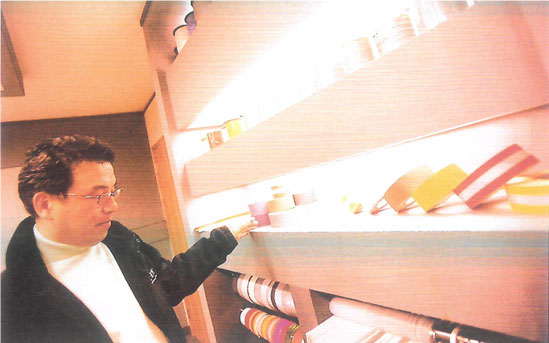

Chairman Choi Sang-seok was honored with the "Trader of the Month" award, jointly organized by KITA, the Ministry of Trade, Industry, and Energy, and the Korea Economic Daily. This award recognizes CEOs with outstanding export performance.

The company rebranded as GIO-FLEX, consolidating its corporate group under GIOLITE-LUMIAN, GIO-FLEX, and GIOTECH-INTERNATIONAL.

A new coating line was added to the second factory.

Traditionally, heat transfer films were primarily purchased by garment factories. However, by launching sales on Amazon, Geoflex made it possible for general consumers to purchase film sheets and apply them using household irons, opening a new distribution channel.

SUEHEUNG REF introduced an automated laser cutting system capable of processing thicker films at higher speeds, automating the entire process from cutting to completion.

The smart factory system improved inventory management, quality control, and automation, enhancing cost efficiency. This innovation facilitated product diversification at GIO-FLEX.

GIOLITE-LUMIAN was recognized as a Global Small Giant, a designation granted to companies meeting stringent criteria such as employment retention, credit rating, and industry scale. This selection acknowledged the company’s strong financial performance and growth potential.

GIO-LIFE started as a fashion mask manufacturer and has since expanded into a comprehensive life-wear and industrial goods company, handling manufacturing, distribution, and sales. During the COVID-19 pandemic, the company supplied fashion masks and later introduced trendy products like grounding shoes.

A third factory was established in Pocheon, featuring expanded coating equipment and hot-melt manufacturing machines. This facility serves as the core of GIO-FLEX's production and operations.

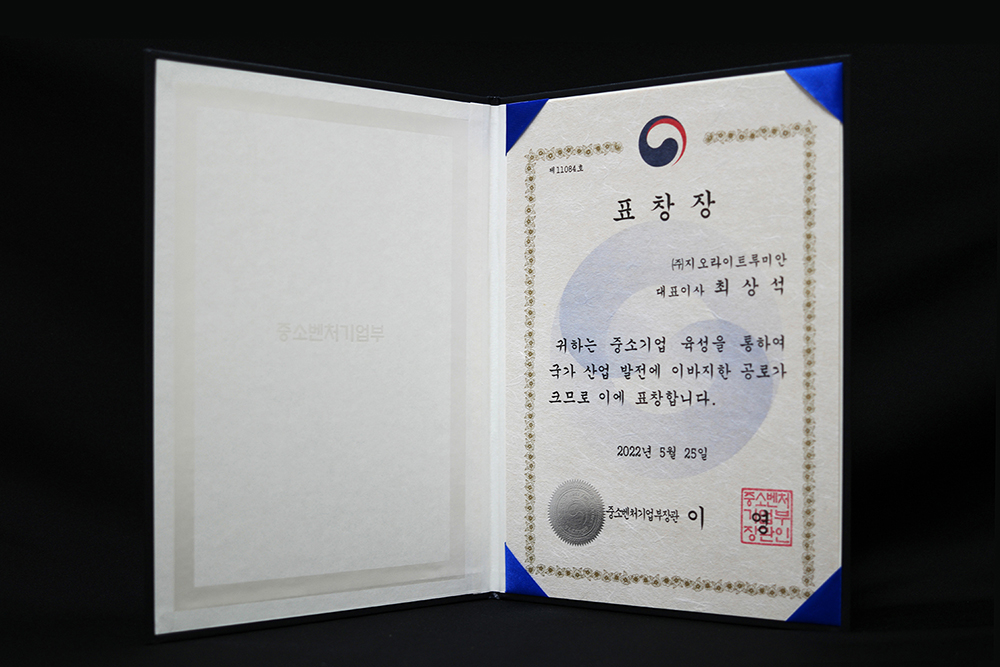

Chairman Choi Sang-seok was recognized for his contributions to the national industrial sector. Having nurtured numerous companies, including SUEHEUNG YANHHAENG, GIOLITE-LUMIAN, and GIOTECH-INTERNATIONAL, he was awarded for his role in advancing industry development.

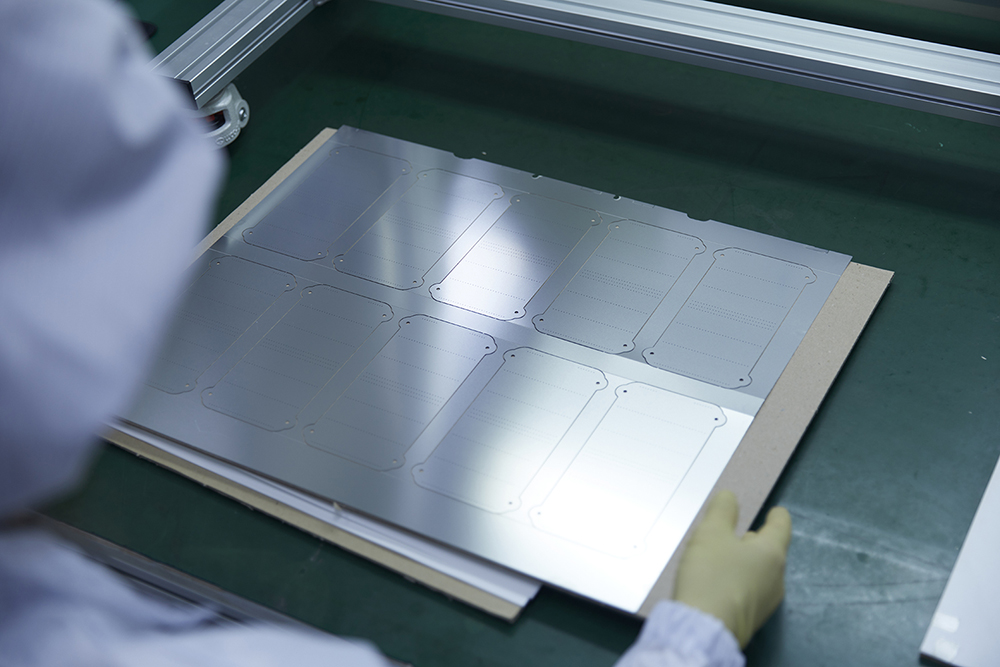

GIONTECH specializes in photochemical metal etching and precision etching technology for semiconductors and electronic components, widely used in the automotive, energy, and electronics industries.

Completion of new factory construction for GIO-FLEX in Pocheon.Launch of the ECO-G FLEX eco-friendly heat transfer film brand.